In the grinding and polishing processes of materials such as optical glass, gemstones, ceramics, and stainless steel, diamond micropowder is a commonly used abrasive material. It can achieve high-precision surface processing, enabling the processed materials to obtain extremely high surface smoothness and precision. For example, in the production of mobile phone screen glass, polishing with diamond micropowder can make the screen surface as smooth as a mirror, improving visual effects and touch feeling.

Learn MoreIn the cold processing of optical glass, diamond micropowder is an important abrasive material. It can perform high-precision grinding and polishing on optical glass, ensuring the flatness and optical uniformity of the glass surface, thereby improving the light transmittance and imaging quality of the optical glass.

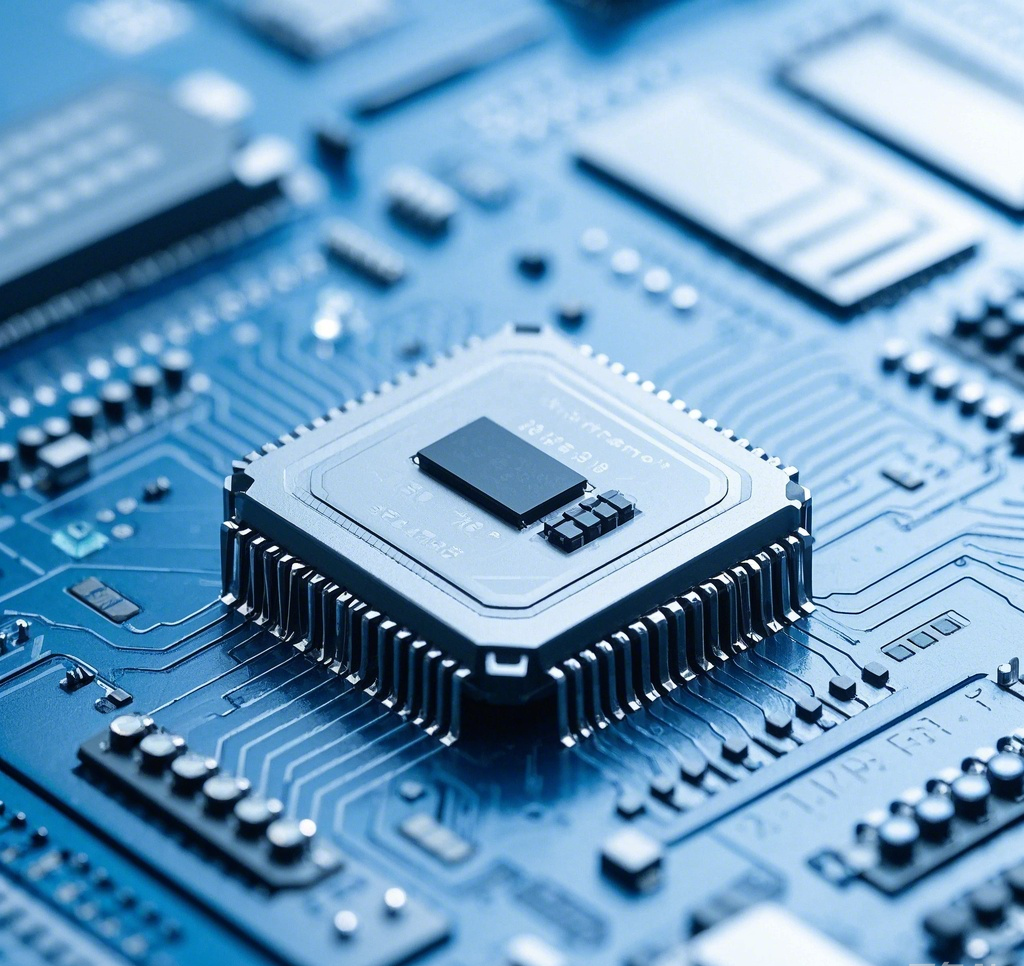

Learn MoreIn the semiconductor chip manufacturing process, materials such as silicon wafers require high-precision cutting, grinding, and polishing. Diamond micropowder, with its excellent performance, has become an indispensable material in semiconductor processing. It can achieve nanometer-level processing precision, meeting the stringent requirements of semiconductor chip manufacturing for material surface quality and Size precision. For example, in the lithography process of chip manufacturing, polishing the silicon wafer surface with diamond micropowder can improve the accuracy of lithography, thereby manufacturing smaller chip components and improving the performance and integration of the chip.

Learn MoreIn the cutting and surface treatment of solar cell silicon wafers, diamond powder plays an important role. It can cut silicon ingots into thin wafers, and in subsequent surface texturing processes, the grinding action of diamond powder is used to form a specific microstructure on the surface of the silicon wafers, increasing light absorption efficiency and thus improving the conversion efficiency of solar cells.

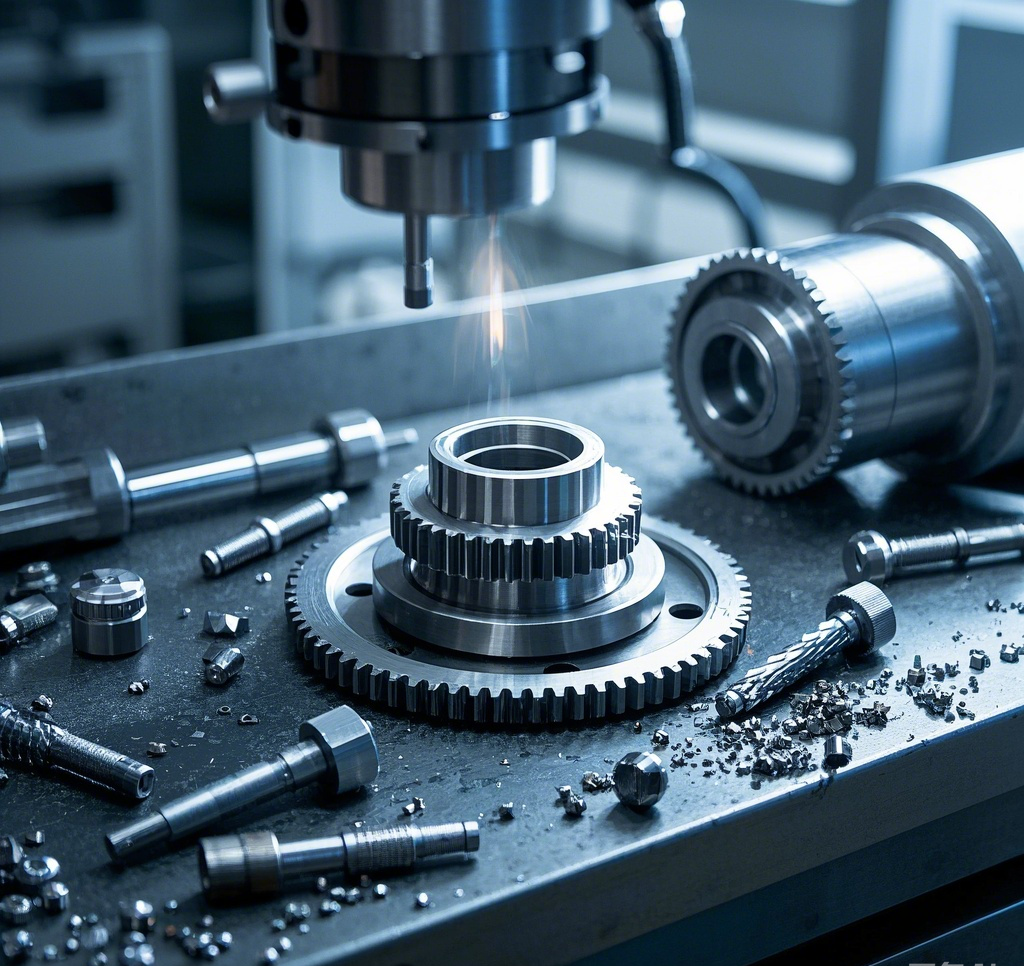

Learn MoreFor some high-precision mechanical parts, such as turbine blades for aero-engines and precision molds, ultra-precision machining using diamond micropowder is required. Through processes such as grinding and polishing, the surface of the parts can achieve micrometer or even nanometer-level precision, meeting the working requirements under complex conditions such as high speed and high temperature. For example, when manufacturing turbine blades for aero-engines, using diamond micropowder for processing can ensure the aerodynamic performance and reliability of the blades, improving the efficiency and performance of the engine.

Learn MoreIn the manufacturing of electronic devices, diamond micropowder can be used in the packaging materials of electronic components. It has good thermal conductivity and insulation properties, and can effectively dissipate the heat generated by electronic components, improving the stability and reliability of electronic devices. For example, in the CPU packaging of high-performance computers, using diamond micropowder as a heat dissipation material can lower the CPU's operating temperature, improving its operating speed and stability.

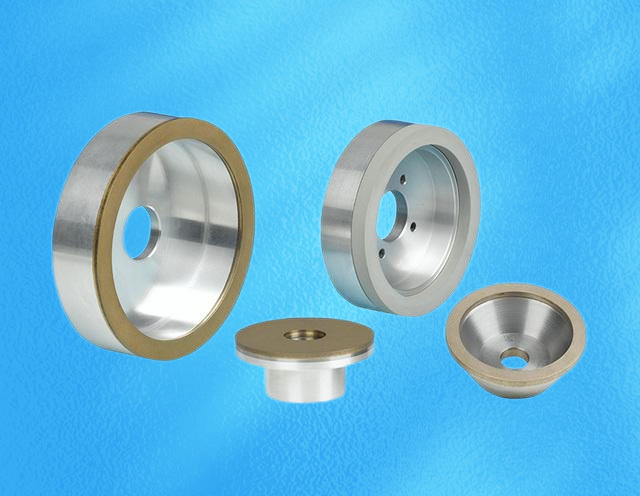

Learn MoreDiamond micropowder is an important raw material for manufacturing various abrasive tools, such as grinding wheels, belts, and polishing pastes. These tools are widely used in mechanical processing, hardware manufacturing, and other industries for grinding and polishing various metallic and non-metallic materials. For example, in the manufacturing of automotive parts, diamond grinding wheels are used to grind engine blocks and crankshafts, ensuring the dimensional accuracy and surface quality of the parts, thereby improving vehicle performance and reliability.

Learn MoreIn the jewelry processing industry, diamond powder is used to grind and polish diamonds, jade, and other gemstones. It can make the surface of gemstones present a brilliant luster, enhancing the quality and value of the gemstones. For example, in the cutting and polishing process of diamonds, diamond powder can precisely shape the facets of diamonds, making them achieve the best optical effect and showing the beautiful fire of diamonds.

Learn More