Exploration of electroplated diamond grinding wheels without dressing

Electroplated diamond grinding wheel is made on the metal substrate

Subcategory: Company Information

Subcategory: Industry Information

2024-06-27

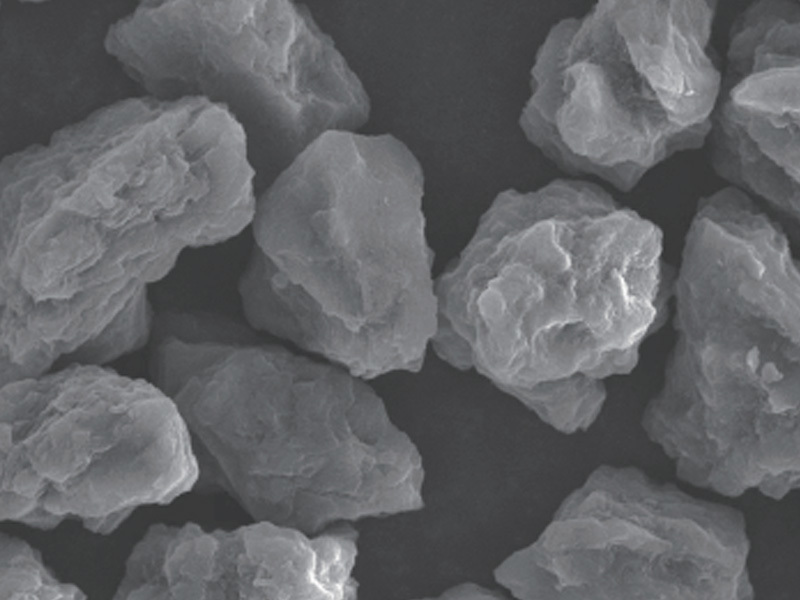

Electroplated diamond grinding wheel is made on the metal substrate by electroplating process to make diamond particles consolidated on the surface of the substrate. The working layer of the grinding wheel contains diamond abrasive grains, and the diamond abrasive grains are bonded to the substrate by a metal bond. First, the thickness of the metal bonding agent is 20% of the height of the diamond abrasive grains (sand), and then the diamond abrasive grains are bonded (thickened) with the metal bonding agent, and the thickness is about 2/3 of the height of the abrasive grains. According to different purposes, can be made into a variety of shapes and structures, such as bowl-shaped, dish-shaped, plane-shaped, etc. in order to grind special-shaped work surface, can also be made into the corresponding shape. The main types of electroplated diamond grinding wheels include diamond dressing grinding wheels, diamond grinding wheels for grinding or cutting. The working surface of diamond grinding wheel has multi-layer and single layer.

Advantages of 2. electroplated diamond grinding wheel

①Compared with the diamond grinding wheel made of resin or bronze bond, it has the characteristics of simple electroplating process, less investment and convenient manufacturing. ②The working surface of single-layer diamond can control the edge of diamond particles during the electroplating process, so the grinding effect of the grinding wheel is sharp and does not need dressing until all abrasive grinding is used. ③The single-layer electroplated diamond grinding wheel can reach a very high working speed, and still have a long life; ④ electroplated diamond grinding wheel can be installed on the grinding machine, can also be installed on the ordinary grinding wheel to replace the silicon carbide grinding wheel; ⑤ electroplated diamond grinding wheel grinding carbide tool has the advantages of high efficiency, small dust, low temperature rise; ⑥ in the grinding wheel substrate with slotting or drilling method, can be made into intermittent work of the grinding wheel. The grinding wheel of this structure has good heat dissipation performance in the grinding process, low temperature rise, and can be dry-ground without cooling liquid. In addition, due to grooving or drilling, the working area is reduced, the amount of diamond is saved, and the cost is reduced; ⑦ for the roller grinding wheel with high precision requirements, electroplating is the best manufacturing method. Because of these advantages, electroplated grinding wheels are widely used in high-speed and ultra-high-speed grinding.

Disadvantages of 3. electroplated diamond grinding wheel

There is no firm chemical metallurgical bond between the coating metal of the electroplated diamond grinding wheel and the bonding surface of the substrate and the abrasive, so the holding force between the abrasive and the substrate is small, the load of diamond abrasive particles is heavy, and it is easy to fall off (or the coating flakes) during high-efficiency grinding, resulting in overall failure. In order to increase the holding force, the thickness of the coating must be increased, thus reducing the chip holding space and the grinding wheel is prone to blockage. At the same time, due to the poor heat dissipation effect, the surface of the workpiece is prone to burns. Therefore, these inherent disadvantages of single-layer electroplated diamond grinding wheel will limit its application in high-efficiency grinding.

The main difference between 4. and other grinding wheels

The difference between electroplated diamond grinding wheel and other grinding wheels lies in the difference of binder. Resin diamond grinding wheel mainly uses phenolic resin and a small amount of metal powder as binder, while electroplated diamond grinding wheel is a grinding wheel production process in which nickel-cobalt and other alloys are deposited on the surface of metal substrate and diamond abrasives are fixed by electrodeposition. The main differences in their performance are: 1. In terms of processing efficiency, because electroplated grinding wheels use higher grade abrasives, in addition, there is only one layer of abrasive, which has advantages in heat dissipation performance, so the processing efficiency of electroplated diamond grinding wheel is higher. 2. In terms of service life, the electroplated grinding wheel has only one layer of abrasive, so the service life of the electroplated grinding wheel will be inferior to that of resin diamond grinding wheel. 3. In terms of processing accuracy, the surface roughness of the workpiece is worse than that of other grinding wheels under the same particle size.

Related Information

Warm winter, warm companion - elements, love and responsibility go hand in hand

At the end of the year, the Spring Festival is approaching, Zhang Yan, general manager of Element, led the volunteers of Element to purchase rice, flour, grain and oil and rushed to nursing homes, orphanages, and poor families to bring a touch of warmth to this cold winter.

Learn More2024/06/27