Application of Diamond Tools in Optical Glass Processing

With the rapid development of the information industry

Subcategory: Company Information

Subcategory: Industry Information

2022-07-28

With the rapid development of the information industry, optical components are widely used in various electronic equipment, the processing accuracy and quality requirements are getting higher and higher, the traditional processing technology and tools are difficult to meet the processing requirements, especially in the diamond tools, regardless of its structure and the inherent quality requirements are more and more specialized, targeted requirements are more and more strong. Therefore, it is more and more important to transform the structure of traditional diamond tools and improve the internal quality in this field.

Diamond tools in this field mainly include milling grinding wheels for milling flat and spherical surfaces in rough machining, edge grinding wheels for edge grinding, fine grinding plates and surface grinding in finishing, super-fine plates and polishing plates. In addition, there are saw blades for blanking, etc.

1. Main types of diamond tools for optical glass processing

milling grinding wheel

The milling of optical glass is the main way of roughing, which is divided into plane and spherical grinding wheels. The diameter of the flat grinding wheel is generally greater than 100mm, while the diameter of the spherical grinding wheel is generally less than 100mm, the grinding wheel size is generally 60#~ 180#, the concentration is generally 50% ~ 100, and the binder is bronze.

diamond edging wheel

Diamond grinding wheel is mainly used for grinding the outer circle of optical parts. Its geometric shape and size are shown in Figure 2 and Table 2. There are two kinds of binding agents, one is electroplated nickel-based binding agent and the other is sintered bronze binding agent. Its particle size is generally between 230/270 -M28/20, with a concentration of 100-200 of electroplating and 50-100 of bronze.

Fine grinding sheet, superfine grinding sheet

The fine grinding plate and the super fine grinding plate are the finishing of the optical parts after the rough machining, so that it can fully show its optical performance when in use. Fine grinding and ultra-fine grinding have plane processing and spherical processing. Fine grinding sheet generally choose bronze, iron-based, nickel-based or cobalt-based binder, and ultra-fine grinding generally use resin organic binder. The particle size of the fine grinding sheet is generally 325/400~10/5, and the concentration is 100 ~ 35%, while the particle size of the ultra-fine grinding sheet is generally in the range of 14/8~7/5, and the concentration is 50% ~ 25%.

Polishing sheet

The polishing sheet is mainly used to improve the surface finish of optical parts, ensure a certain aperture, and reduce the processing of surface deterioration layer. The main shape is like a fine grinding plate and a super fine grinding plate, the binder is resin, the abrasive is cerium oxide and a small amount of diamond powder.

2. Reasonable choice of diamond products in optical glass processing

The reasonable choice of diamond products in optical glass processing mainly refers to the selection of the shape and size of diamond tools, bond type, diamond particle size, diamond concentration, bond hardness and so on according to the shape, grade, processing quality requirements and processing technology of optical glass components being processed. The general principles of selection are:

(1) according to the processing method and the accuracy of the machine tool to choose the shape and size and accuracy of the diamond tool.

(2) according to the processing of the original margin and surface roughness to select the size of the diamond tool.

(3) The concentration of diamond is selected according to the size of the workpiece, the processing procedure and the coverage ratio of the diamond tool, especially for fine grinding and ultra-fine grinding.

(4) Select the type of binder according to the process of processing the workpiece and the grade of the workpiece, especially for fine grinding and ultra-fine grinding. Like fine grinding generally choose bronze, nickel-based, cobalt-based and iron-based. Selection of bronze and nickel base for finishing of soft glass. The hard glass and the glass with high viscosity are selected from iron base and cobalt base.

(5) according to the processing of optical parts of the brand, hardness and brittleness to choose the hardness of diamond tools and bond strength. In general, the hardness of soft glass and brittle glass selection binder is lower; the strength of the binder is smaller. And hard, brittle glass to choose higher hardness; bonding agent strength.

3. New manufacturing technology of diamond tools for optical glass

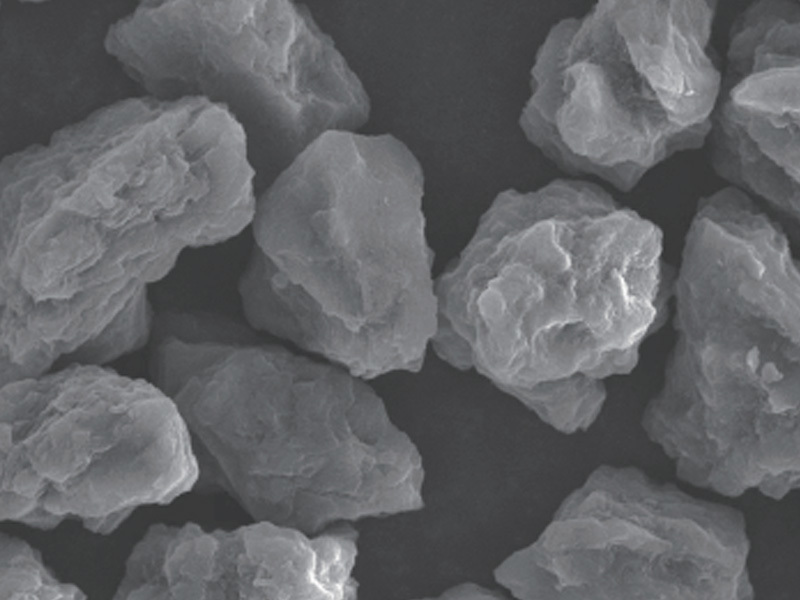

At present, the manufacturing technology of diamond tools in this field is getting higher and higher, mainly in the following aspects: in terms of raw materials, the powder of binder is getting finer and finer, the general particle diameter is less than 40μm, and some can reach below 10μm, and all are pre-synthesized powder.

The range of diamond particle size composition is getting narrower and narrower, and the crystal shape is getting better and better, especially in the micro-powder grade, which is almost equal to the volume. Trace elements and compounds are added to various binders to improve the efficiency of their grinding. The distribution of the diamond in the binder is generally achieved by a granulation process or by thorough homogeneous mixing. The molding sintering adopts the hot pressing sintering method with protective atmosphere.

Mold using high-precision high-temperature metal mold, burned out of the blank almost no pores, and diamond in the sintering process almost no reduction in strength, the manufacture of the blank must undergo strict finishing, to ensure its surface and tolerance, while ensuring its grinding sharpness.

4. Problems and Countermeasures of Some Diamond Tools in Optical Glass Processing

Diamond tools often have a variety of problems in the process of using, which affect the yield and efficiency of processing, and have a great impact on production costs and product performance. This is mainly manifested in the manufacturing technology and inherent performance of diamond tools.

milling process

The following main problems often occur in the milling process:

(1) Roughness difference

(2) Glass beating and chipping

(3) Unstable profile

(4) Low efficiency and deep scratches

These problems are mainly related to the particle size, concentricity, concentration, self-sharpening of the bonding agent and the life and durability of the grinding wheel. To solve these problems from the analysis of the manufacturing technology of the grinding wheel, the strength of the bonding agent and the diamond concentration and particle size are mainly adjusted. At the same time, the concentricity of the grinding wheel must be guaranteed. Mainly to improve the holding strength of the diamond and reduce the grinding hardness of the bonding agent.

Fine grinding and super fine grinding and polishing process

Fine grinding, ultra-fine grinding and polishing process is the most critical process of optical glass processing, but also the most prone to quality problems of several processes. The diamond tools in this process are also the most difficult to make, the main problems in the process are as follows:

(1) the workpiece is easy to produce pitting

(2) Aperture instability and irregular aperture

(3) Poor surface roughness

(4) Edge breakage or crack of workpiece

(5) regular scratch or irregular scratch

(6) Easy passivation of grinding disc

(7) low cutting efficiency

Most of these problems are related to the quality of diamond tools and should be improved from the following aspects:

(1) Choose the appropriate diamond concentration, generally the diamond concentration is high.

(2) Improve the self-sharpening of the binder, mainly to reduce its grinding hardness and uniformity, and reduce the segregation of low melts.

(3) Reduce the coverage ratio of diamond chips, reduce the grinding surface area of diamond chips, or increase the chip space.

(4) Reduce the dispersion of diamond particle size and the irregularity of shape. No large particles are allowed, and no more fine particles are allowed.

(5) the addition of trace elements in the binding agent to change the nature of the binding agent.

(6) grinding fluid to add a small amount of fine abrasive particles.

(7) improve the resin water resistance and temperature resistance, improve its thermal conductivity.

(8) Reduce the pores in the pellets and reduce the crystal size of the binder.

Related Information

Warm winter, warm companion - elements, love and responsibility go hand in hand

At the end of the year, the Spring Festival is approaching, Zhang Yan, general manager of Element, led the volunteers of Element to purchase rice, flour, grain and oil and rushed to nursing homes, orphanages, and poor families to bring a touch of warmth to this cold winter.

Learn More2024/06/27