Multiple applications of diamond in new energy vehicles

Electroplated diamond tool refers to a diamond tool

Subcategory: Company Information

Subcategory: Industry Information

2024-06-27

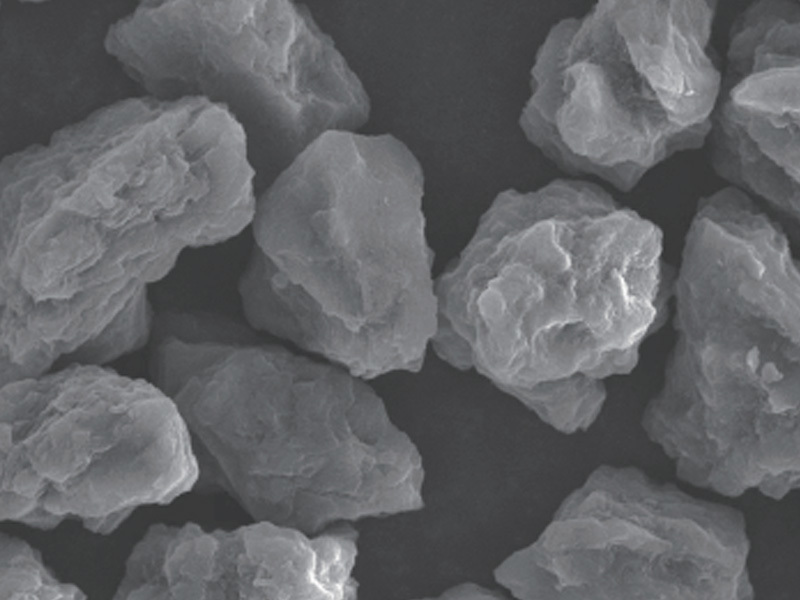

Electroplated diamond tool refers to a diamond tool made by metal electrodeposition method to make diamond firmly wrapped in matrix metal (steel or other materials). It is widely used in machinery and electronics, glass, building materials, oil drilling and other industries. With the development of economy, the progress of science and technology, the requirements of different industries for electroplated diamond tools are basically the same, that is, high efficiency, long life and high grinding accuracy. In order to ensure these characteristics, the coating metal should not only have high hardness and wear resistance, but also be evenly distributed in all parts of the substrate to avoid the coating falling off and shorten the tool life. In some special industries, such as the magnetic material industry, the feed rate of strong grinding is controlled at about 0.3mm. The dry grinding with large feed rate in the ceramic industry requires particularly harsh binding force between coated metal and steel substrate. In the production process of electroplated diamond tools, most manufacturers only pay attention to the type, hardness and wear resistance of the coated metal, and often ignore the problem of the binding force between the coated metal and the substrate. In the actual use process, the phenomenon of coating shedding is common. This paper analyzes the causes of this problem and discusses the solutions.

2. Types of coating shedding

Electroplated diamond tools in the use process due to the use of conditions such as grinding force, temperature rise, the impact of the workpiece and other reasons will cause the phenomenon of metal coating containing diamond and steel substrate separation, which is the coating off. Coating shedding is generally a rare phenomenon of partial shedding of coating at one time. In the actual use of the process of coating off the situation is roughly the following three:

(1) The coating falls off to the surface of the substrate: that is, the metal coating containing diamond and the metal bottom coating without diamond are separated from the steel substrate at the same time.

(2) The layer falls off to the metal bottom coating: that is, the metal bottom coating without diamond is not separated from the steel substrate, but the metal coating containing diamond is peeled off from the metal bottom coating.

(3) The layered separation of the coating metal in the diamond-containing metal coating: the coating metal in the contact part of the diamond-containing metal coating with the workpiece during use is not normally worn but abnormally shedding into pieces or powder. The diamond is not all shedding but local granular shedding. The consequence of this phenomenon is not easy to attract attention is that the product life is short, which often gives the illusion of poor holding force or wear resistance of the coated metal. Excluding factors such as coating scorching and poor wear resistance of coated metal during thickening, the falling off of diamond particles during normal use of tools is visually manifested as the falling off of such coatings when there are continuous and large holes on the surface of the tool.

3. Causes of coating shedding

Electroplated diamond tools involve multiple processes in the manufacturing process. Any process that is not fully carried out will cause the coating to fall off.

Effect of 3.1 pre-plating treatment

The treatment process of the steel substrate before entering the plating tank is called pre-plating treatment. The pre-plating treatment includes mechanical polishing, degreasing, etching and activation. The purpose of the pre-plating treatment is to remove burrs, oil, oxide film, rust and oxide skin on the surface of the substrate to expose the substrate metal so that the metal lattice grows normally to form intermolecular bonding force. If the surface of the substrate is not well treated before plating, there is a very thin oil film and the metal lattice of the oxide film substrate metal cannot be fully exposed, which will prevent the coating metal and the substrate metal from forming intermolecular bonding force.

Therefore, poor pre-plating treatment is the main cause of coating shedding.

Effect of 3.2 plating solution

The formulation of the plating solution directly affects the type, hardness and wear resistance of the coating metal with different process parameters can also control the thickness of the coating metal crystallization, density and the size of the internal stress of the coating. For the production of electroplated diamond tools, the vast majority of nickel or nickel-cobalt alloys are used if the influence of plating bath impurities is not considered:

(1) The influence of internal stress The internal stress of the coating is that the additives and their decomposition products and hydroxides in the solution produced during the electrodeposition process will increase the internal stress. This stress is caused by lattice defects caused by some deposition factors in the plating process. In particular, the effect of certain metal ions and organic additives can significantly increase the internal stress of the coating. There are two types of internal stress in the coating: macro stress and micro stress. Macroscopic stress is manifested in the bending of a metal sheet by the influence of the internal stress of the coating. Microscopic stress is mainly expressed by increasing the hardness of the coating.

Macroscopic stress can cause bubbles, cracking and falling off of the coating during storage and use.

For electroplating nickel or nickel-cobalt alloy, the internal stress of different plating solution composition is very different. The higher the chloride content, the greater the internal stress. For the main salt of nickel sulfate plating solution, the internal stress of Watt plating solution is less than that of other types of plating solution. The macroscopic internal stress of the coating can be significantly reduced and the microscopic internal stress can be increased by adding organic brighteners or stress relief agents. Different process combinations such as current density, PH value and temperature can make the coating of the same plating solution have different internal stress. Therefore, in order to reduce the influence of internal stress, the process range of the plating solution must be strictly controlled so as to ensure that the internal stress of the coating is within the range of process requirements.

(2) Effect of Hydrogen Evolution A certain amount of hydrogen ions are always present in any plating solution due to the dissociation of water molecules regardless of its pH value. Therefore, in the case of appropriate conditions, whether in acidic, neutral or alkaline electrolyte plating on the cathode and metal precipitation at the same time often have hydrogen evolution. Hydrogen ions in the cathode after the reduction of a part of the formation of hydrogen escape part of the atomic hydrogen state into the base metal and coating. Distorting the crystal lattice causes a large internal stress and also deforms the coating significantly. At this time, although no defect was seen from the appearance, its mechanical properties were unacceptable. During the use of the tool, when the temperature of the surrounding medium rises, the adsorbed hydrogen accumulated in the base metal or the coating metal will expand and cause the coating to bubble and fall off.

When the current efficiency of nickel plating cathode is 95%, only 5% is hydrogen evolution reaction. However, if the temperature is too high and the pH value is too low, the improper components will aggravate the hydrogen evolution. Therefore, how to control the hydrogen evolution reaction during electroplating to control the internal stress of the coating is a problem worthy of discussion.

Effect of 3.3 plating process

If the composition of the plating solution and other process control effects are excluded, the power failure in the plating process is an important reason for the coating to fall off.

The electroplating production process of electroplated diamond tools is quite different from other types of electroplating. The electroplating process of electroplated diamond tools includes empty plating (bottoming), sanding and thickening processes. In each process, there is the possibility of long or short power-off of the substrate leaving the bath. For example, after a certain period of empty plating, it is necessary to observe the quality of bottom nickel and whether diamond is evenly distributed on the substrate. In the above process, if there are sand planting and sand unloading steps, sand unloading sometimes needs to leave the plating tank and carry out in another tank. During the thickening process, observe whether the diamond coverage rate is in place, etc. Short-term power-off has little effect on the coating. If the power-off time is too long, a dense oxide film will be generated on the metal surface of the coating in an instant, so that the subsequent electrodeposition of metal atoms cannot grow along the original metal lattice to affect the binding force of the two.

When the external force is greater than the binding force between the two layers during the use of the tool, the separation of the layers between the two layers is inevitable. Therefore, the use of more reasonable process, process can also reduce the phenomenon of coating off.

4. Measures to Solve Coating Shedding

In view of the above reasons for the coating shedding, the author thinks that the following measures can be taken to solve the problem of coating shedding:

(1) Strengthen the pre-plating treatment as far as possible to completely remove the burrs, oil, oxide film, rust and oxide skin on the surface of the substrate to promote the normal growth of the coating metal lattice to improve the binding force between the coating metal and the substrate metal.

(2) Optimize the plating solution formulation and plating process, adopt charged into the tank to prevent bipolar phenomenon. For workpieces with complex shapes, use short-time high current to impact empty plating to reduce the internal stress of the coating and the influence of hydrogen evolution phenomenon to improve the quality of the coating.

(3) Optimize the process and reduce the power-off time when unloading sand, even continuously unload sand in the original sand tank, thicken or charge sand in a spare tank to improve the binding force between diamond particles and coating. In case of power failure during the thickening process, the workpiece shall be put into the electrolyte for cathodic reduction and then charged into the bath for electroplating to ensure the coating binding force.

5. Conclusions

In the production process of electroplated diamond tools, in the selection of a certain composition of the plating solution formula, in addition to considering the hardness and wear resistance of the coating metal, we should also pay full attention to the qualitative measurement of the internal stress of the coating and the influence of various additives on the internal stress. At the same time, in the production process, full attention should be paid to the production process control specifications for each step of pre-plating treatment to ensure that the plating solution is clean and the impurity content is within the process range. Only in this way can we ensure the production of high-quality and stable quality electroplated diamond tools.

Related Information

Warm winter, warm companion - elements, love and responsibility go hand in hand

At the end of the year, the Spring Festival is approaching, Zhang Yan, general manager of Element, led the volunteers of Element to purchase rice, flour, grain and oil and rushed to nursing homes, orphanages, and poor families to bring a touch of warmth to this cold winter.

Learn More2024/06/27