Magnetic Separation and Magnetic Susceptibility of Diamond

Pure natural diamond is a non-magnetic substance

Subcategory: Company Information

Subcategory: Industry Information

2021-11-12

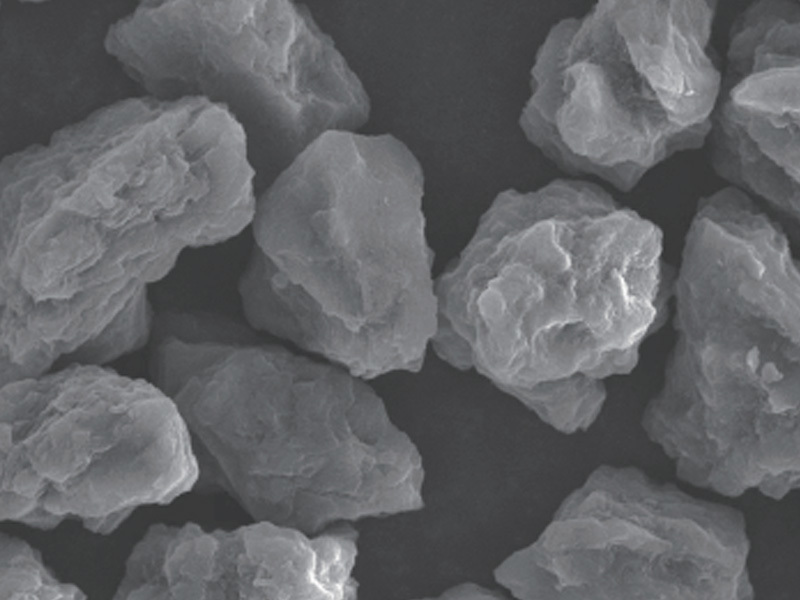

Pure natural diamond is a non-magnetic substance. When synthetic diamond is synthesized by high pressure method, metal alloys such as Fe, Co, Ni and Mn are commonly used as catalysts to promote the nucleation and growth of diamond. A small amount of catalyst as impurities in the diamond growth process is wrapped in the diamond particles, resulting in the internal defects of the diamond, and the diamond has a certain magnetic. At the same time, under the high-temperature conditions of manufacture and use, the diamond abrasive grains are prone to crack, so that the strength is drastically reduced. Therefore, in the process of diamond production, it is necessary to separate the diamond abrasive grains with different impurity contents, and to detect the impurity content of different grades of diamond products to make them meet the standards. In recent years, with the increasing development of diamond scientific research and production in China, people are increasingly aware that magnetic sorting of diamond products can draw diamonds with different qualities and suitable for different occasions, so that the application of diamond is more reasonable after classification.

A basic principle of magnetic separation

Magnetic separation is a method of sorting diamonds by the action of magnetic and mechanical forces on diamonds. Due to the different magnetic ability of magnetic particles and non-magnetic particles, the resulting motion trajectory is also different, the magnetic force of the strong magnetic particles is greater than the mechanical force, so they are attracted to the magnetic roller and rotate with the roller. When the magnetic roller rotates to the area outside the action of the magnetic field, the magnetic particles fall off the roller or are swept by the brush and enter the magnetic product hopper; the non-magnetic particles are carried out of the magnetic field by the trough and enter the non-magnetic product hopper because the magnetic force is less than the mechanical force. In this way, different magnetic diamonds can be divided into magnetic, medium magnetic, non-magnetic or weak magnetic products by changing the magnetic field strength. The magnetic separation process is shown in the figure below.

diamond single crystal, fine grain diamond, synthetic diamond, diamond

Magnetic susceptibility of two synthetic diamond abrasives

1. Definition of magnetic susceptibility in electromagnetics

Material according to its magnetic can be divided into diamagnetic, paramagnetic, ferromagnetic and so on. When a substance is placed in a magnetic field with a magnetic field strength H, it will be magnetized, and the degree of magnetization is represented by the magnetization M. For substances other than ferromagnetic substances, experiments show that there is a proportional relationship between M and H, namely:

M=XmH

Xm is called magnetic susceptibility and is a dimensionless constant. Xm for diamagnetic materials is negative, Xm for paramagnetic materials is positive, and Xm for vacuum is zero.

Magnetic susceptibility is an inherent property of matter, independent of its shape and size.

2. Magnetic susceptibility of diamond abrasive

Synthetic diamond magnetic size not only with its internal impurities and inclusions content, composition has a direct relationship, but also with other physical and chemical properties and quality indicators (such as: toughness, strength, specific gravity, thermal stability, color, transparency, etc.) and use and classification has a close relationship. For example, it is reflected in another important test index of diamond thermal shock toughness (TTI), that is to say, the higher the magnetic susceptibility of diamond, the lower the thermal shock toughness, the easier it is to break at high temperature, and the lower the strength. Therefore, the magnetic separation of diamond has a very important significance for sorting out different quality diamonds. The diamond abrasive sample in production is a large number of unrelated particles, so the measurement result is the average magnetic susceptibility of all the measured particles. Sorting products must be tested by magnetic susceptibility to meet the requirements of control standards, to ensure the reliability and consistency of product performance, so that the production of product performance remains unchanged for many years. For manufacturers, it is an essential means of detection. The magnetic susceptibility of each metal is different, so the magnetic susceptibility of each manufacturer is not comparable due to the different catalyst systems used, but for the diamond synthesized by the same catalyst, the magnetic susceptibility classification is still effective.

Related Information

Warm winter, warm companion - elements, love and responsibility go hand in hand

At the end of the year, the Spring Festival is approaching, Zhang Yan, general manager of Element, led the volunteers of Element to purchase rice, flour, grain and oil and rushed to nursing homes, orphanages, and poor families to bring a touch of warmth to this cold winter.

Learn More2024/06/27